Why SLA 3d printing?

A polished surface. Prepares well for metal plating or painting.

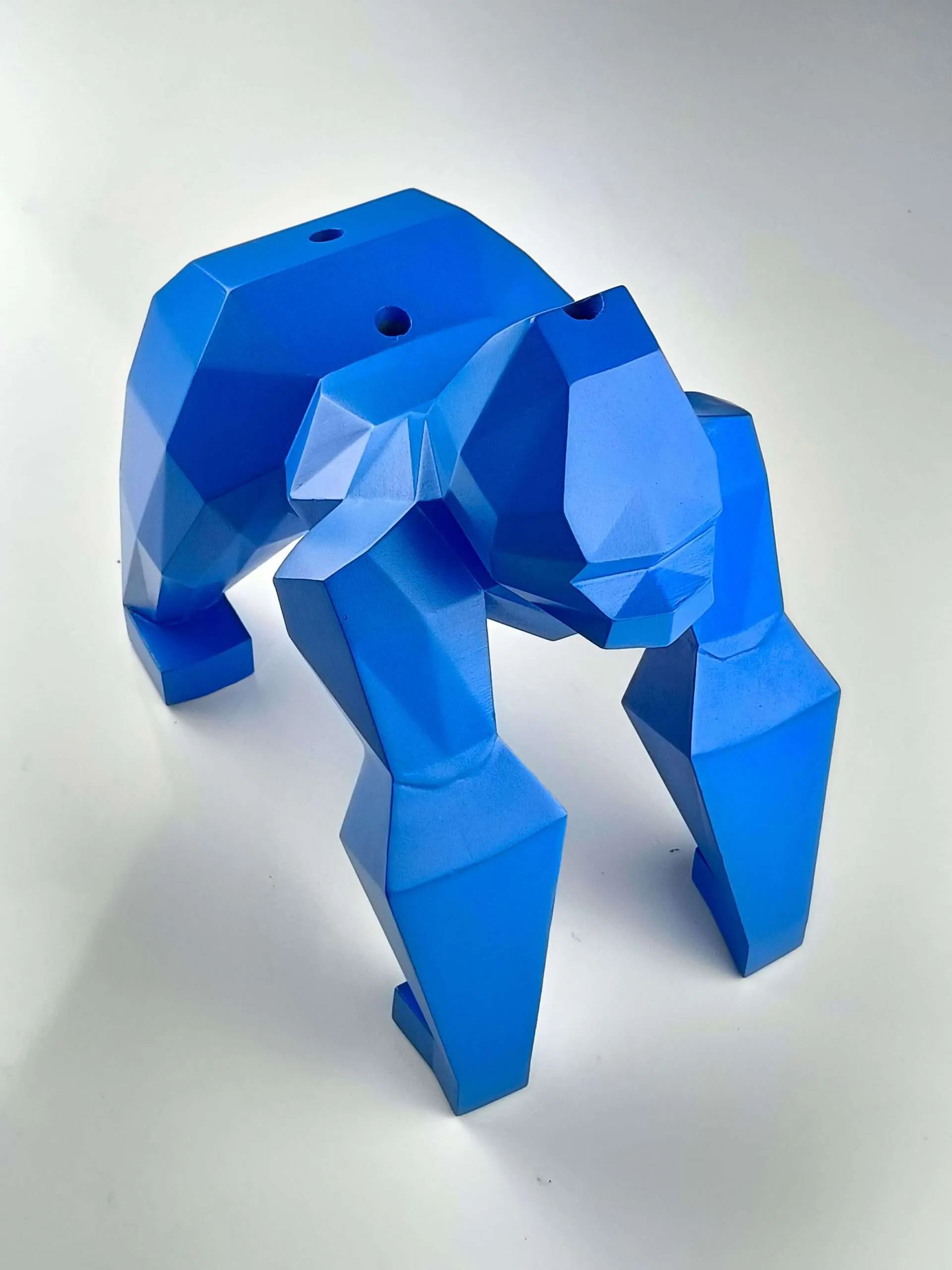

Ability to print intricate and complex pieces.

Unlike FDM prints, layer lines are invisible out of the printer.

3D printing on a large scale is feasible.

Flexibility in materials! Various materials, various goals.

High precision and accuracy.

Why Choose Our SLA 3D Printing Service

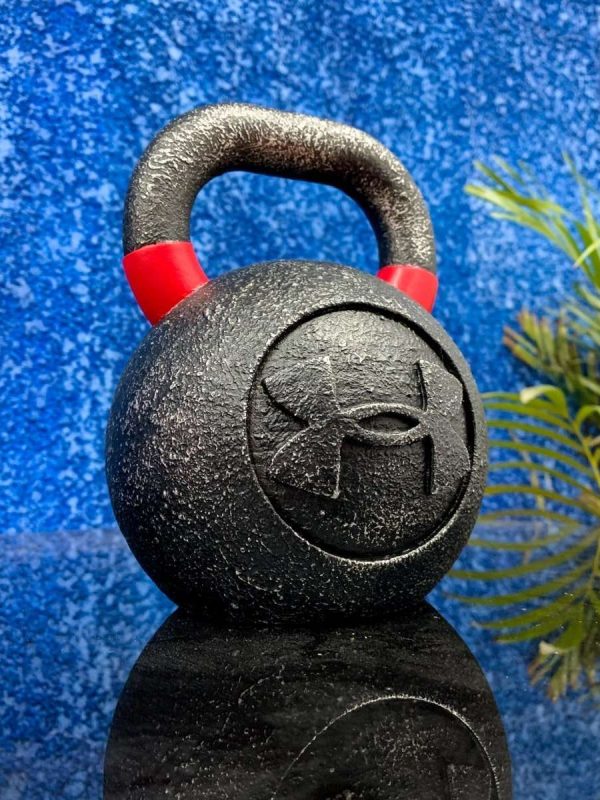

Quality Finishing

We do all the rough and hard work, from support cleaning, UV curing and even polishing.

Get expert help

SLA 3D printing is one of the major technologies we use in 3D Printing as there is a high demand on it. We’ve worked on hundreds of SLA printing projects and we know exactly how to get the best outcome for your project.

access to expensive industrial 3d printers

With the industrial 3d printers we have, you can 3d print large scale models or print multiple high-detailed parts in no time!

SLA 3D Printing Applications

Rapid protoyping

Quickly build accurate and high-resolution prototypes.

Complex 3D Printed models

Denture production

3D printing revolutionizing denture production, making it more affordable and efficient.

Our materials for SLA

Ready to start your project?

Feel free to contact us if you have any questions!

FAQs about our SLA 3D Printing Services

We started with FDM printers but we quickly outgrew them. We realized just how painful it is to clean each prints and, even then, the quality is still not what we want. It has its use but we just believe that stereolithography SLA printing technology is the obvious choice for most of the projects that we do.