AUTOMATION Benefits

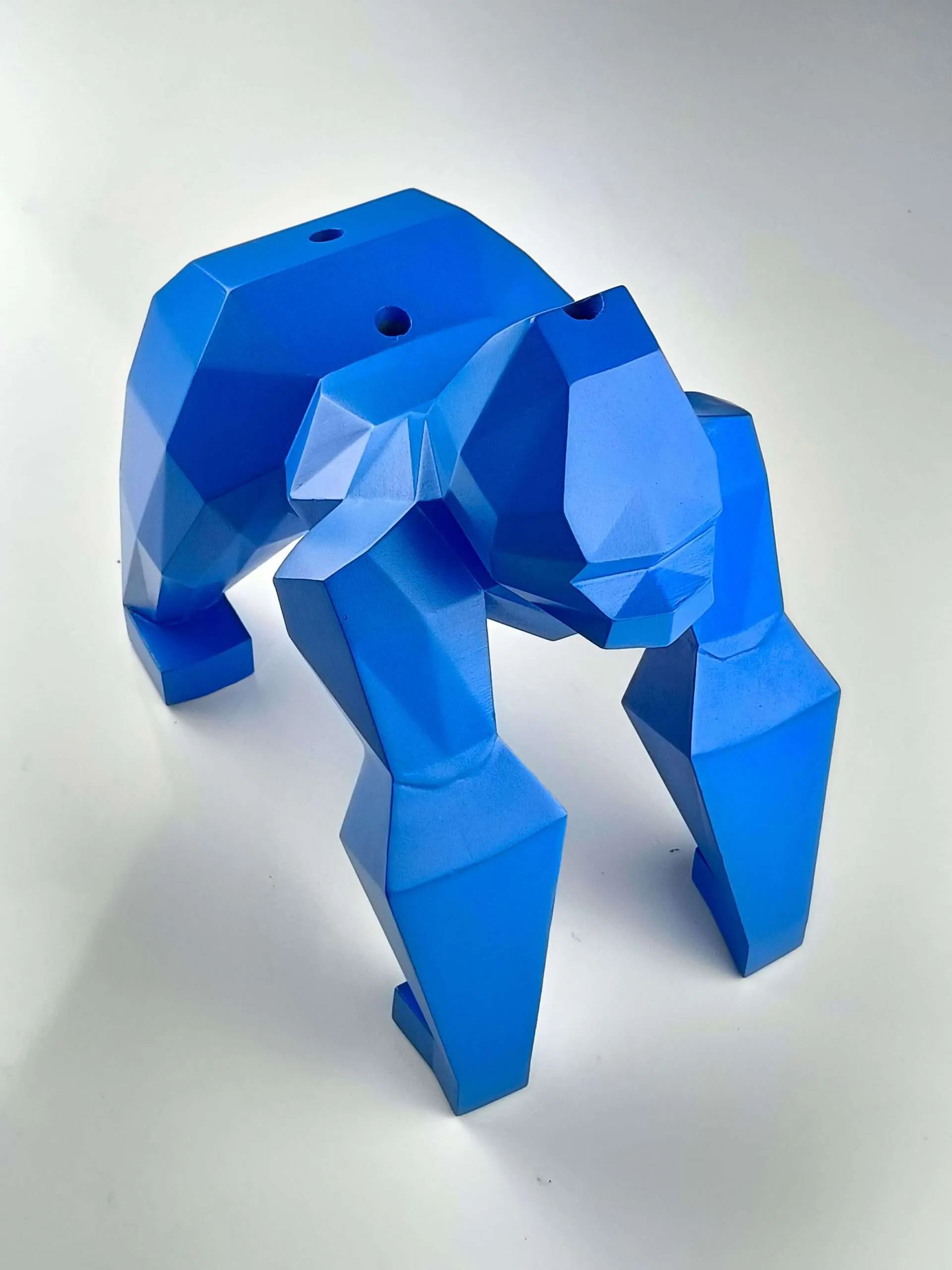

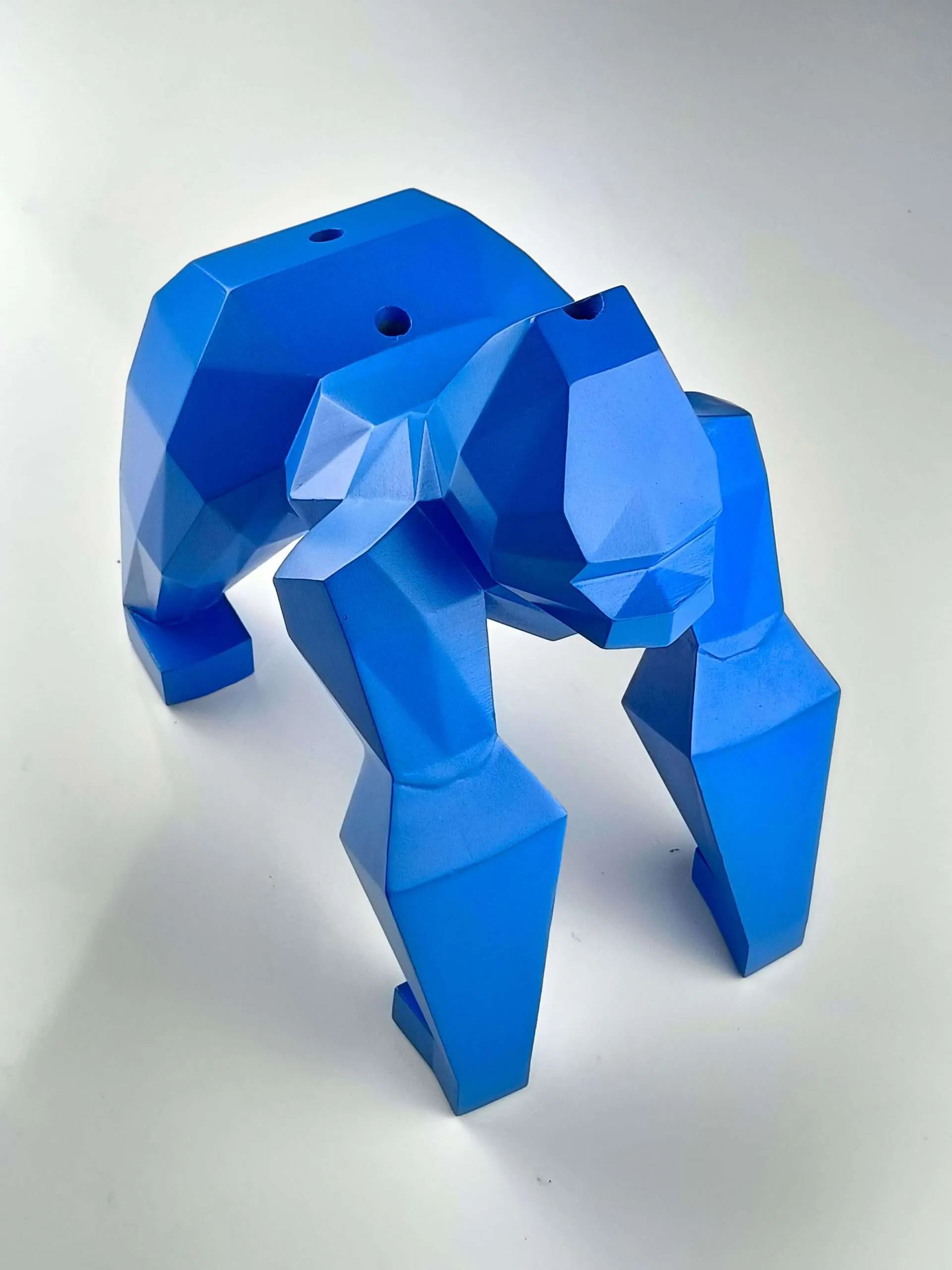

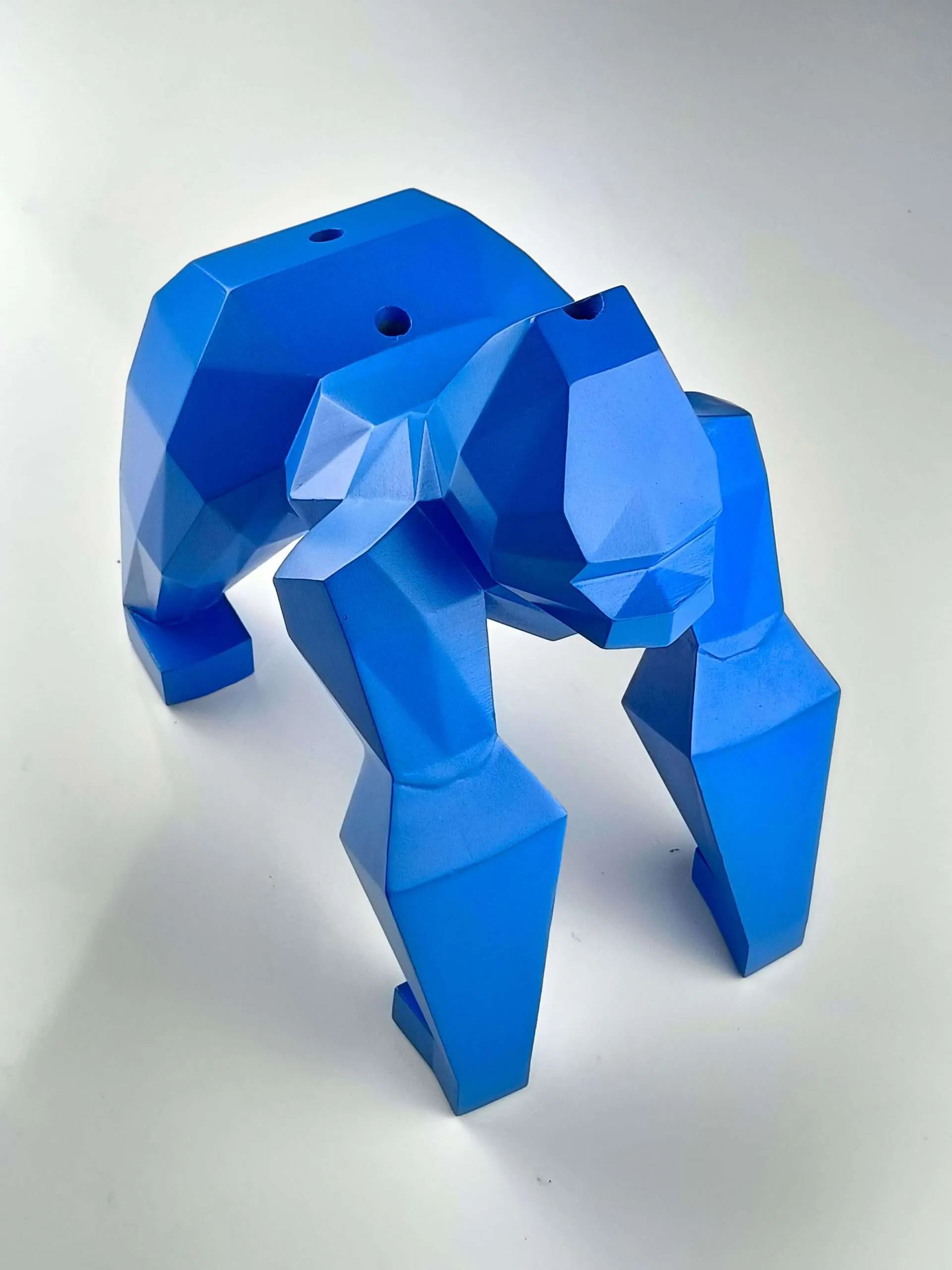

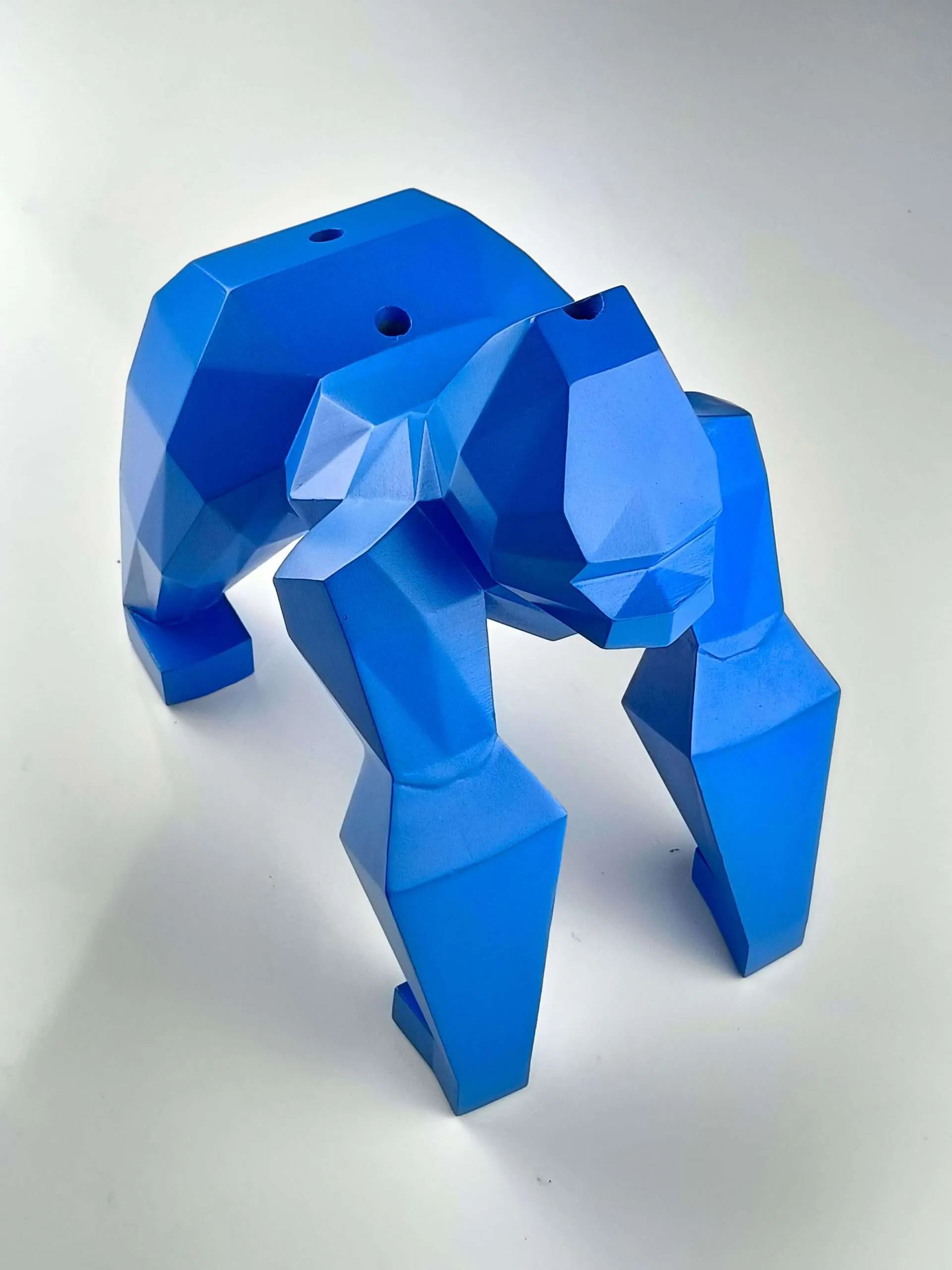

- Moving objects always have a strong influence over our vision and are more captivating to the audience. We imitate those attractive features into your prototype so that it would grab the attention of its surrounding and indulge them with your product.

- Your ideas will be able to propagate more effectively to the target audience with the realistic visualization of your products in the form of automated prototypes.

- Adapting automation would broaden your vision for innovative products and improve your brand awareness among the masses as an evolutionary enterprise.

WHY CHOOSE US

EXPERT HELP

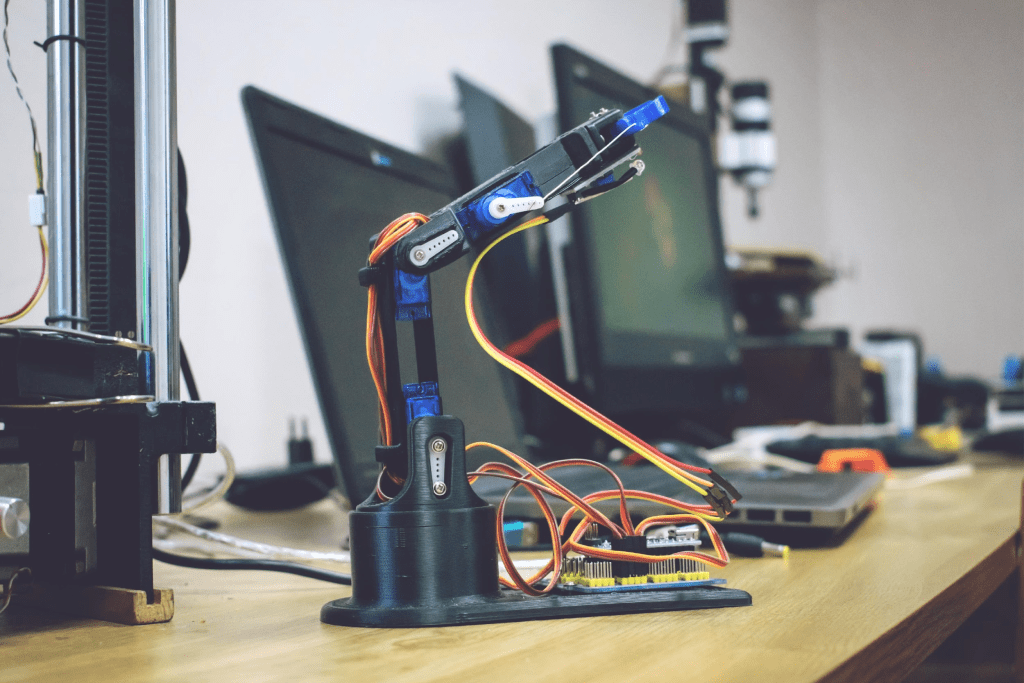

Looking for a dynamic prototype for your project? Let’s make your high-quality 3D prints move too with our wide range of automation solutions.

Our experts can help you implement the best custom Automation solution for your project.

FULL SERVICE AUTOMATION

We’ll handle everything, from Design to Manufacturing & Integration for your project.

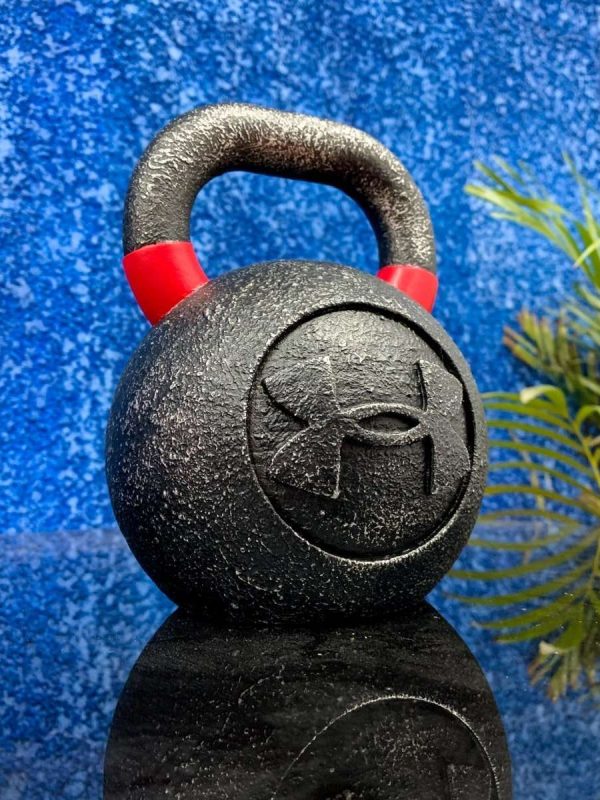

PREMIUM QUALITY PRODUCT

Get a fully customized automation solution with highest-efficiency for your project.

FAST TURNAROUND

At 3Distica, we deliver with lightning quick turnarounds with fully functional prototypes.

OUR SERVICES

01

Large Scale Automation

For Businesses from various industries like; Construction, Healthcare, Education, Exhibitions, Events, Automotive and Entertainment We offer custom automation solution to cater for your project visualizations, advertisement and other dynamic products manufacturing.

02

Medium Scale Automation

For Individuals and Educational Institutes. From adding subtle motion to automating entire prototype, we got you covered!

OUR PROCESS

01

Tell us what you need

The project name, scale and a brief description. If you’re unsure, we can guide you towards the perfect solution!

02

Receive a Quote

You’ll get an email and a call from us immediately so we can discuss the best and most cost effective way to approach your project.

03

Building your project

Once approved, we will start developing your project. You will be continuously updated on the progress

04

Availability

We provide automation services across UAE, Saudi Arabia, Kuwait, Qatar, Bahrain, Oman, Jordan, and the rest of the Middle East.

Ready to start your project?

Feel free to contact us if you have any questions!

AUTOMATION FAQS

This can completely vary depending on the design and complexity of your project. Simple projects can be completed as quickly as 1-2 weeks, whilst other, more complicated ones can take up to 4-6 weeks or more. We aim to deliver in the most time and cost-effective way.

The cost of our automation services vary with the complexity of solution design, materials etc. Get in touch for cost estimation.

At 3Distica, Automation services are designed to take ideas and deliver highly automated functional prototypes; so an idea really is all you need

Get in touch to discuss your ideas with us. So our Automation services can bring your imagination to life.

Good to Know the Differences

Fused Deposition Modeling

Fused Deposition Modeling, or FDM, is an additive manufacturing process in which a machine precisely extrudes melted plastic

filament to create a part. FDM machines excel at large-format 3D printing and typically can be used with a wider variety of plastic materials compared to other

processes. FDM parts exhibit a clean finish on the vertical edges with visible stepping between layers that becomes most prominent on gradual and organic contours. Top- and bottom-facing features

will show the filament contours

Stereolithography

Stereolithography, or SLA, is a 3D printing process that uses a UV-curable liquid resin, called a photopolymer, to build parts in high detail. SLA is highly accurate and can be used with a variety of engineered resins, including clear materials, to create prototypes and concept models. SLA parts typically have a smooth plastic-like finish

Selective Laser Sintering

Selective Laser Sintering, or SLS, is an additive manufacturing process that

uses a laser to fuse thin layers of polymer powder together to create parts. Similar to HP MJF, SLS does not require support structures 一 this combined with end-use material properties makes SLS a widely used process for prototypes and end-use products alike. SLS parts have a matte or sugar-cube like finish but can be postprocessed for smoother results

How Our Automation Service Works

01

SEND A 3D FILE

Send us your 3D file. We accept the commonly used .stl, .obj or any other format. If you do not have a design file

ready, we provide superior design services as well. Check out our 3D odeling section

02

SHARE MORE DETAILS

Let us know anything that will help us get a better understanding of your project in terms of technology, material, finsih and quantity. If you are unsure about it, don’t worry. We will help you to get the best results.

03

PROJECT REVIEW

We will reach out to talk about the most effective way to deliver your project. No minimum quantity!

04

START PRINTING

As soon as the approach and cost are approved, your idea will start having a physical form!

05

RECEIVE YOUR ORDER

We offer domestic and international shipping.

We will make sure your order arrives to your doorstep safe and sound! Worried about assembly and installation for large scale objects? Leave that to us as well

3D Printing Materials We offer

Looking for a material that isn’t listed here? Shoot us an email at [email protected]