WHY CHOOSE US?

Fast Turnaround

At 3Distica, we handle your project from start to finish and deliver your product in a fast turnaround.

WE'RE DETAIL ORIENTED

When it comes to Customizing Classic Car Parts, we are the one that you can count on. We have a sharp eye on details and measurements to make sure you will have a masterpiece added to your car.

GET EXPERT HELP

With our expertise in the field of custom manufacturing, we’re here to assist you in your projects. Get in touch for further discussion.

HOW IT WORKS

01

UPLOAD YOUR 3D MODEL

Send us a 3D model or we can create one for your project, just share your ideas with us.

02

WE'LL REVIEW YOUR MODEL

We’ll check if your model has any issues and with our expertise in the domain we will guide you which materials are the best to use in your design.

03

START 3D PRINTING

Your Customized Classic Car Parts will begin printing.

Good to Know the Differences

Fused Deposition Modeling

Fused Deposition Modeling, or FDM, is an additive manufacturing process in which a machine precisely extrudes melted plastic

filament to create a part. FDM machines excel at large-format 3D printing and typically can be used with a wider variety of plastic materials compared to other

processes. FDM parts exhibit a clean finish on the vertical edges with visible stepping between layers that becomes most prominent on gradual and organic contours. Top- and bottom-facing features

will show the filament contours

Stereolithography

Stereolithography, or SLA, is a 3D printing process that uses a UV-curable liquid resin, called a photopolymer, to build parts in high detail. SLA is highly accurate and can be used with a variety of engineered resins, including clear materials, to create prototypes and concept models. SLA parts typically have a smooth plastic-like finish

Selective Laser Sintering

Selective Laser Sintering, or SLS, is an additive manufacturing process that

uses a laser to fuse thin layers of polymer powder together to create parts. Similar to HP MJF, SLS does not require support structures 一 this combined with end-use material properties makes SLS a widely used process for prototypes and end-use products alike. SLS parts have a matte or sugar-cube like finish but can be postprocessed for smoother results

Custom Classic Car Parts Services We Offer

01

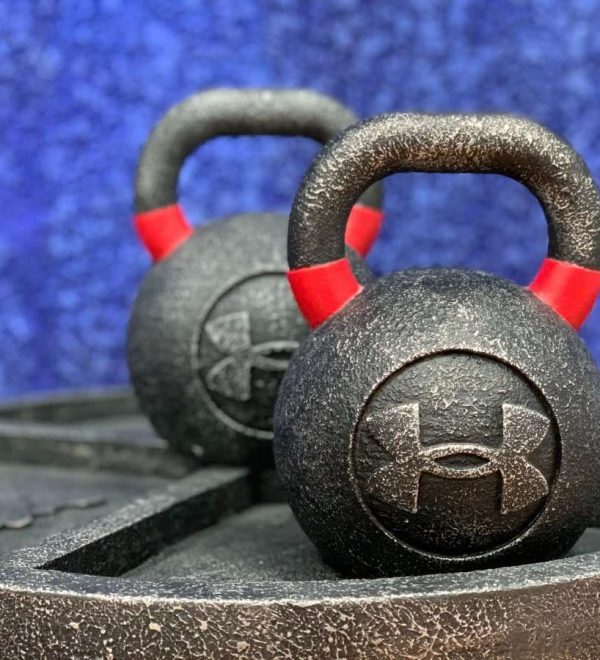

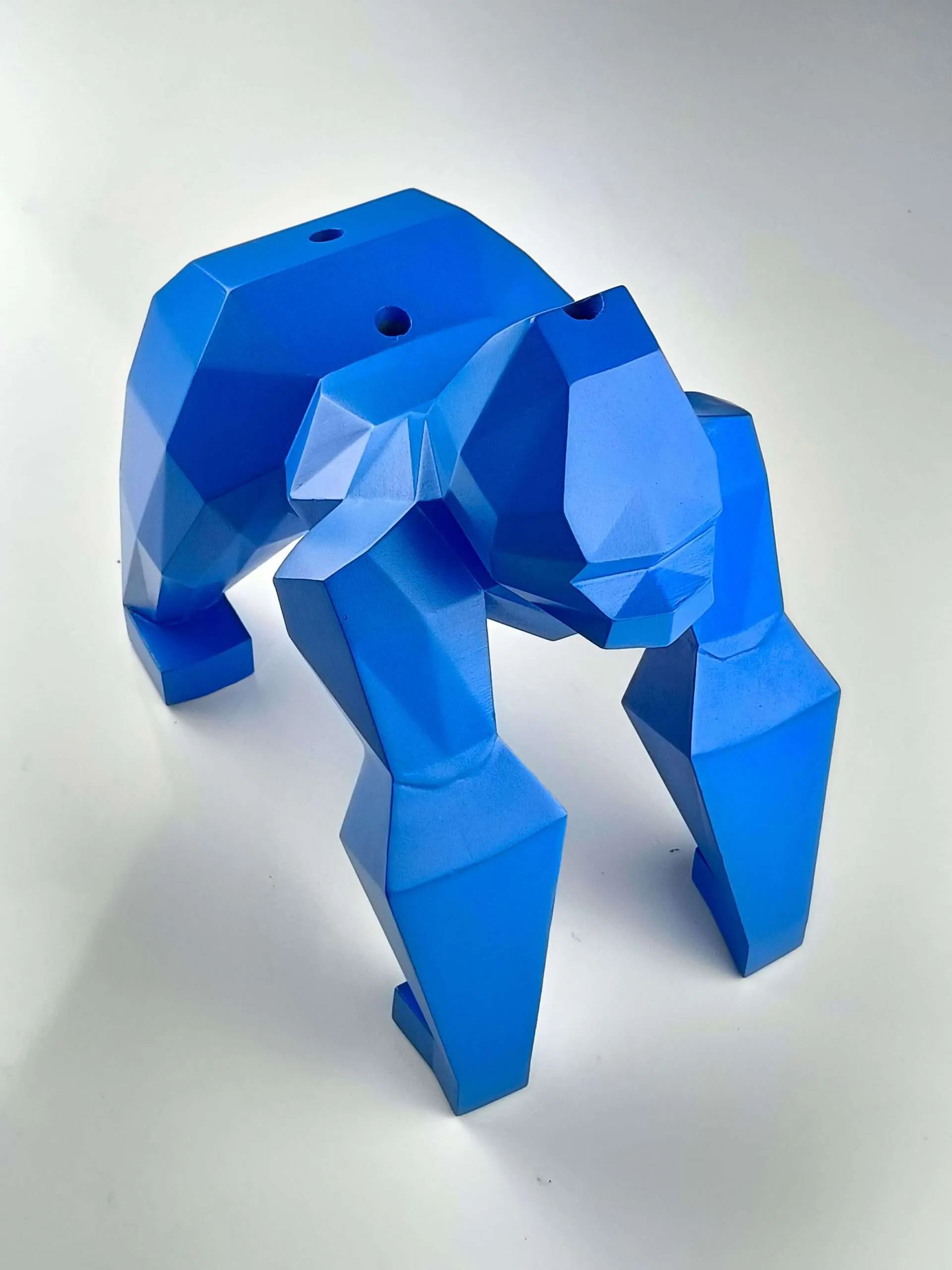

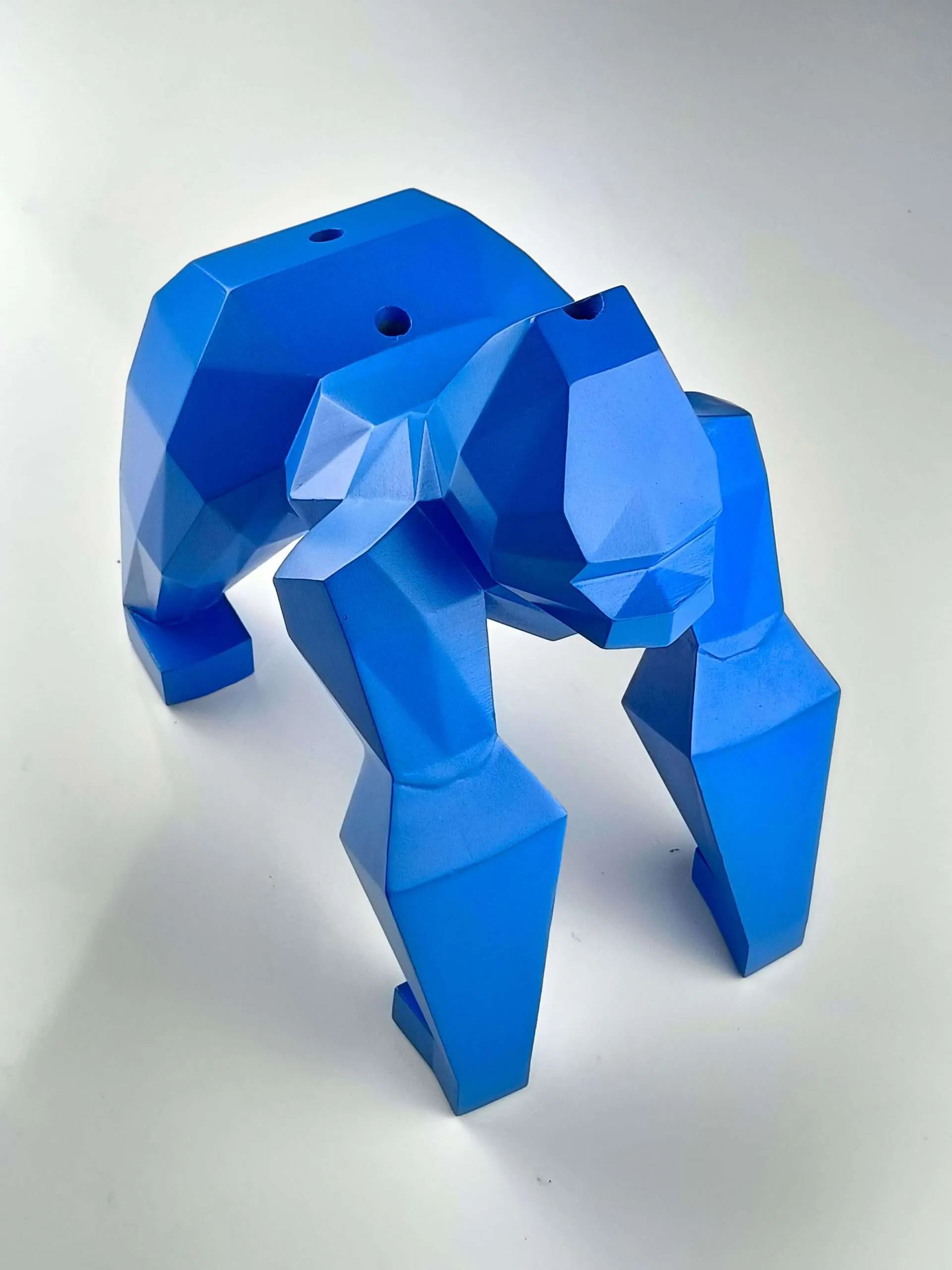

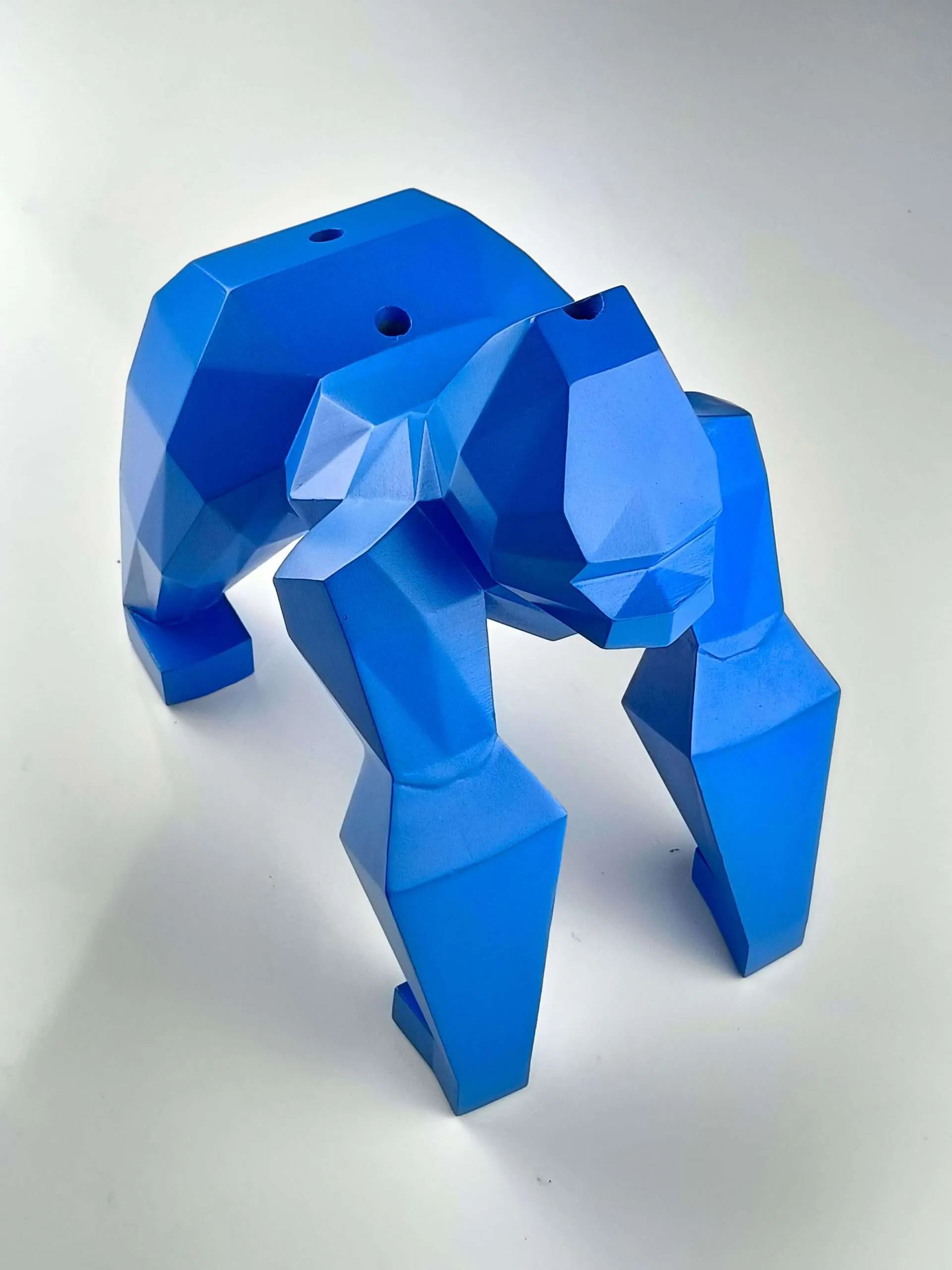

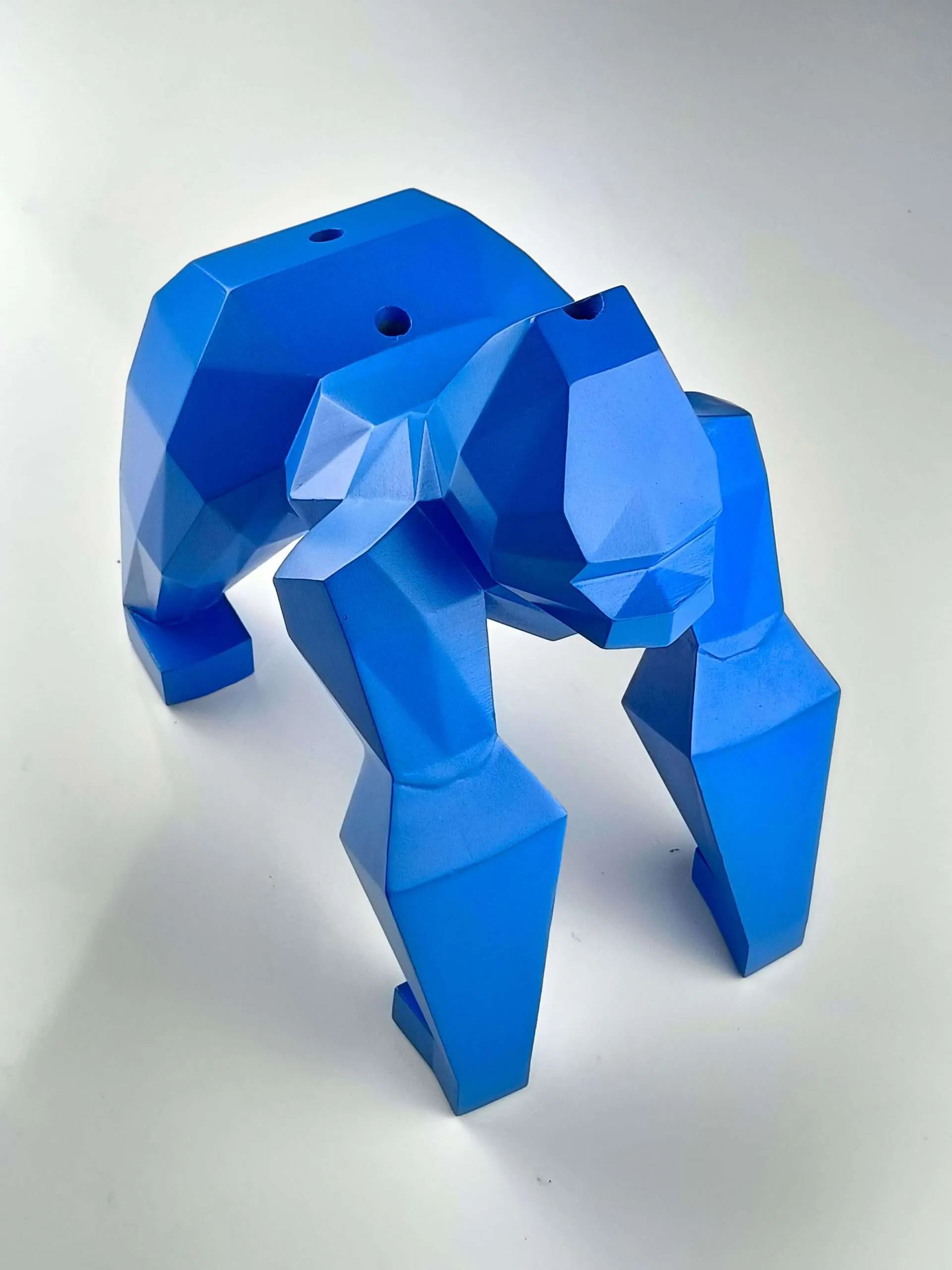

Large Scale 3D Printing

At 3Distica, we offer 3D printing services for projects of any size, including large scale and high-volume printing. Our expertise, hands-on approach and advanced 3D printing technologies allow us to deliver large-scale 3D printed objects on time. If you are looking to 3D Print a large-scale model for architectural, engineering, or artistic projects. Get in touch today!

02

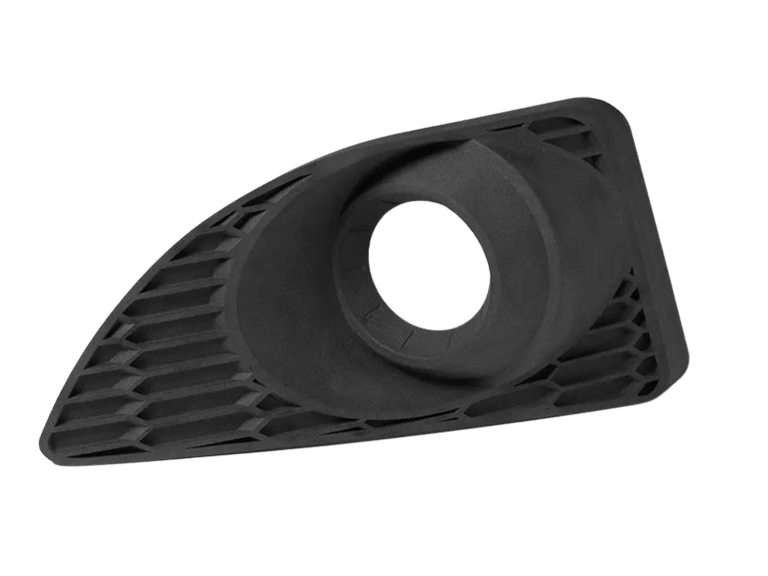

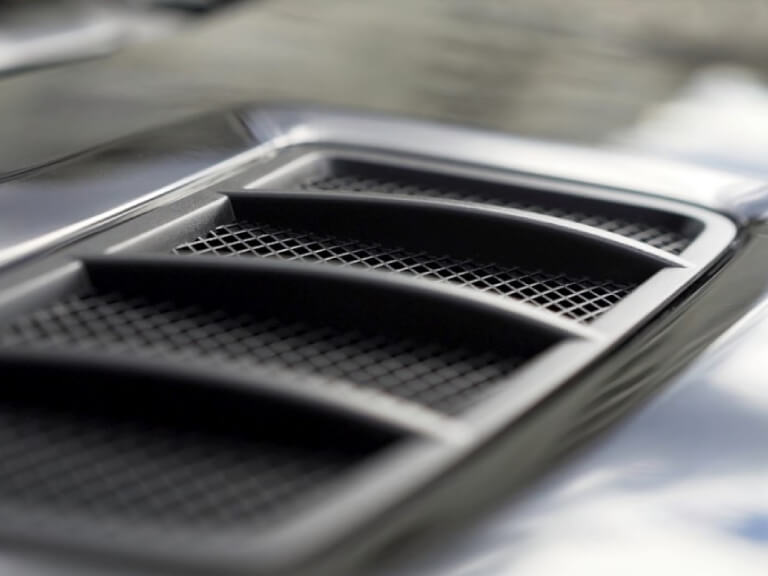

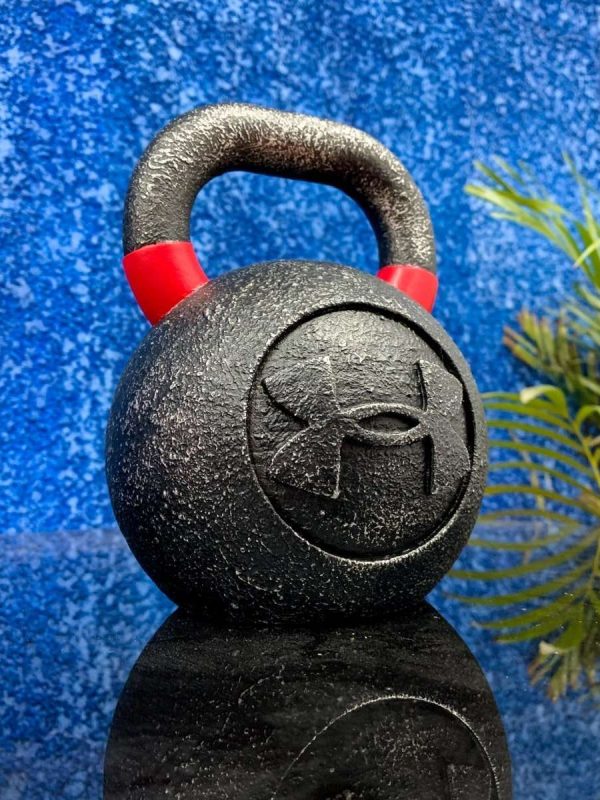

Custom Classic Car Parts

Revamp your classic car with custom parts. Experience the perfect blend of vintage charm and modern functionality.

03

Custom Awards & Trophies

Recognize excellence with custom awards and trophies. Celebrate your champions in style.

How Our Custom Classic Car Parts Service Works

01

SEND A 3D FILE

Send us your 3D file. We accept the commonly used .stl, .obj or any other format. If you do not have a design file

ready, we provide superior design services as well. Check out our 3D odeling section

02

SHARE MORE DETAILS

Let us know anything that will help us get a better understanding of your project in terms of technology, material, finsih and quantity. If you are unsure about it, don’t worry. We will help you to get the best results.

03

PROJECT REVIEW

We will reach out to talk about the most effective way to deliver your project. No minimum quantity!

04

START PRINTING

As soon as the approach and cost are approved, your idea will start having a physical form!

05

RECEIVE YOUR ORDER

We offer domestic and international shipping.

We will make sure your order arrives to your doorstep safe and sound! Worried about assembly and installation for large scale objects? Leave that to us as well

3D Printing Materials We offer

Looking for a material that isn’t listed here? Shoot us an email at [email protected]

Ready to start your project?

Feel free to contact us if you have any questions!

FAQS

We print diverse variety of fully customized classic car parts such as engine parts, dashboard components, door handles, emblems (logo), knobs, trim pieces, and more.

The materials used vary depending on the part’s function, appearance, and durability requirements. Some popular materials include PLA, ABS, Nylon, PETG, and more specialized materials such as carbon fiber or metal composites.

With our printers and cutting-edge technologies, we can make 3D printed classic car parts with tolerances of up to 0.1 mm or even less, making them appropriate for various automotive applications.

Definitely, 3D printing can be a useful technique for replicating rare or difficult-to-find classic car parts that are no longer manufactured. A new part can be developed by 3D scanning an existing part and developing a 3D model.

3D printing classic car parts offer several benefits, including the ability to create customized parts, faster prototyping, lower costs, and the ability to produce parts on demand.

Yes, 3D printed parts can be used in real cars. We ensure that the parts designed and printed meet the safety and durability requirements.